Ted Scott

February 29, 2024

All business processes are built on planning. It is an important part of management activity. On the basis of plans the strategy is chosen, the direction of enterprise development, resources and methods are formed to achieve the set goals. Strategic plans outline the desired picture of long-term and structural changes to improve the competitiveness of the organization. They are made for a long-term period: from three to seven years. The sphere of strategic planning includes setting the main goals, approving the mission, forecasting the conditions in which the company will have to work.

Operational planning is used for more detailed management of work processes in the company. This management tool helps to coordinate and distribute resources, load on employees, funds, equipment. Responsible for the smooth operation of each department, division involved in the development, manufacture and sale of products. Organizes its regular and systematic production in the approved volume and nomenclature.

What it is: concept, difference from strategy

Operational planning of the enterprise’s activity is a system of measures to develop detailed production plans for a month, week, day, shift. The main difference between an operational plan and a strategic plan is the duration of the period covered, the degree of detailing of tasks. Their other differences are:

-

Strategic planning is the prerogative of the company’s managers. Operational plans are made by middle or lower level managers.

-

Strategy development takes a long time to prepare. Operational tasks are solved on a daily basis.

-

Strategic plans always provide for several alternatives. Operational alternatives are not foreseen.

-

The company’s strategy is developed taking into account internal and external sources of information. Internal data is sufficient for operational plans.

Operational and production planning includes methods, techniques and tools for calculating the main planning indicators taking into account the analyzed period. At this stage of planning, a list of documentation is approved. It is determined what methods will be used to calculate the main indicators. A preliminary forecast of the company’s activity is drawn up, taking into account the previously developed strategy.

Goals, objectives and principles

The main purpose of operational planning is to ensure full-fledged, efficient work of all departments, shops and subdivisions of the enterprise. The tasks of operational planning include:

-

Rhythmic production of goods due to even load of all shops and sections;

-

Fulfillment of the plan on assortment, terms;

-

Rational loading of the company’s equipment, fixed assets and employees;

-

Reducing the length of the production cycle with a reduction in the size of unfinished products.

By doing them, the following results can be achieved:

-

Improve the productivity of employees, encourage them to develop and be active;

-

Reduce the cost of production;

-

Increase the level of involvement of fixed assets and working capital.

The operational planning system is built at several management levels:

-

At the general level, the planning and economic department and other divisions of the company are responsible for drawing up plans.

-

At the level of departments or other structural units, planning and dispatching bureaus are involved in this process.

-

At the level of individual production sites, planning is carried out by the company’s engineering staff. This includes foremen, site managers, department heads and other personnel.

Operational planning is based on the following principles:

-

Flexibility. The plans necessarily include a reserve that allows the company to make certain maneuvers without deviating from the chosen course due to external circumstances.

-

Continuity. Plans are drawn up systematically based on the analysis of achieved results.

-

Holism. All elements of the operational plan should be linked. The department plan is part of the higher-level planning.

-

Specificity. Operational and ongoing plans need to be clearly and concisely described for early achievement.

When planning, it is important to observe the “principle of comprehensiveness”. All approved plans, documentation and reports created as part of the company’s activities should complement each other.

Types and stages of operational planning

Any plans developed for a business can be defensive or offensive. Offensive tactics are used by large, stable companies that have enough resources at their disposal to grow. Entrepreneurs typically use defensive tactics to help hold onto positions they have earned in the marketplace. A type of defensive planning is liquidation plans, which are developed to eliminate unprofitable lines of business, getting rid of unprofitable departments.

The main stages of operational planning:

- Calendar planning. It includes the creation of tasks for manufacturing and production output on the basis of production programs with bringing them to the responsible executors and providing them with the necessary resources. It is divided into two types:

-

inter-shop, based on links between separate divisions of the company to coordinate their joint work (for example, between main and auxiliary shops);

-

in-house, ensuring uninterrupted operation of individual lines, sections and units.

- Dispatching is an action aimed at monitoring the production progress in accordance with the approved schedule, performed by special services: dispatch bureaus. Based on the information received from departments, they make decisions on making adjustments to the production process.

Operational planning systems include:

| Sub-detail system | It is practiced in companies with an established production cycle, producing homogeneous products. It provides regulation of all operations affecting the company’s work processes (provision of services, production of goods). Plans are drawn up taking into account the rhythm of work of all departments of the company, for a day, shift, hour or week. |

|---|---|

| Order system | Suitable for firms with small volumes of products or services, characterized by a heterogeneous product mix. The units of measurement in this case are production orders consisting of homogeneous work. The system is based on the calculation of production cycle times. |

| Complete | It is in demand in mechanical engineering and other serial production. Its planning and accounting unit is a part or a set of parts that are grouped together according to common features. Tasks are issued for the total amount of work or by sets per assembly. |

| Production control by tact | It is used to adjust the time of all technological operations taking into account the total estimated time. Large-scale annual plans are divided into smaller ones, distributing tasks among all departments of the company. This takes into account the labor intensity of the processes and the approved delivery dates. |

Operational planning methods

The main operational planning techniques include:

-

The volumetric method helps to distribute the annual output and sales volume over shorter periods (day, week or month). With the help of this method the potential costs of the company are forecasted. Monthly programs for shops and departments are created. The deadlines for the fulfillment of orders or production of finished goods are planned.

-

The calendar method is used to approve normative duration of working cycles with indication of start and end dates of the period of production of the final product. On the basis of this methodology programs for shops are developed.

-

The volume-calendar method helps to plan terms and volumes of work, in general, for the enterprise for a month, quarter, year or other period. It is used to develop monthly programs of producing and non-producing shops.

-

The volume-dynamic method considers the timing, volumes, dynamics of production of goods or services. It more fully takes into account the demand of consumers. On its basis, it is used to build plans-schedules of loading of shops that manufacture products or purchase lists of customers.

Creation of operational plans in the enterprise

Operational planning in production begins with the preparation of a general annual plan. Then it is detailed by shops and individual structural subdivisions. This is done in the following way:

-

An annual or quarterly production program is formed.

-

Allocated to shorter periods. Specified by shops, departments, sections or brigades.

-

Monthly scheduling plans are formed.

-

Reporting plans are made.

-

Plans are made for shifts.

-

Control, monitoring of the work process is carried out. Necessary adjustments are made if necessary.

The monthly shop floor production plan takes into account: production program, labor, wage and cost indicators.

Automation of planning

Without a detailed operational plan, work in a manufacturing company will turn into chaos. Without a strategy or a master plan, the company can still exist for some time. But without daily planning, its activities will be chaotic and disorganized. Each employee, coming to work, should have a work plan for the day or shift. It can be communicated verbally or by using modern IT technologies.

The use of cloud services saves money by eliminating the need for a company to maintain its own servers. The tools at their disposal will ensure that incoming data is processed quickly. Thanks to this it is possible to quickly adjust the plan taking into account newly arisen circumstances. The use of electronic planning services in marketing makes it possible to analyze the composition and nature of the target audience. It provides a clear budget allocation, helps to better promote the market through the formation of attractive offers for customers.

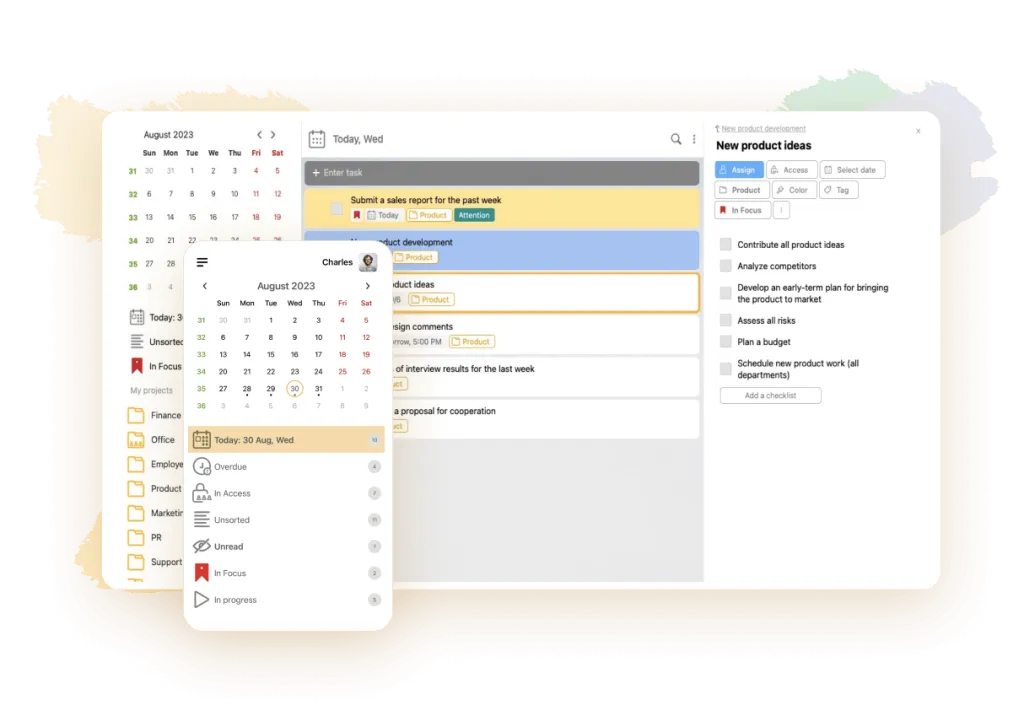

Operational planning in LeaderTask

LeaderTask is a reliable and effective tool for strategic, operational and current planning. It is suitable for personal use, companies of all forms of ownership, entrepreneurs and freelancers. It combines the capabilities of a planner, task manager, personal secretary and CRM system.

In the application you can create to-do lists and tasks for a day, week, month or other period. Manage projects. Delegate tasks to subordinates and colleagues. Create detailed schedules for a day or a week using a calendar. Create tasks with set deadlines, prioritize execution. Track employee performance and progress on charts. Evaluate task completion based on statuses. Visualize goals, to-do’s on kanban boards. Optimize the process of communication and interaction with customers. Save all important information in a single database with the ability to restrict access.

The program will help managers and businessmen to highlight key goals and focus on their achievement. It will ensure efficient work with the company’s operational and current plans. Control the execution of all tasks and assignments. The planner synchronizes with many digital services, works on any device, including offline.

Conclusion

Effective development of enterprises in the modern market economy is impossible without the development and implementation of a structured system of operational planning. Without its application in the field, even with the most competent management, it will not be possible to achieve strategic goals. Business will not be able to compete with other market participants on equal terms. This will inevitably lead to a decrease in profitability, deterioration of labor conditions and remuneration.

Development of operational production plans is a systematic, regular activity of managers and executors, which helps to successfully perform tactical, current and then global tasks of the organization. Implementation of operational planning systems has a positive impact on the performance of personnel. The manager can clearly see how the employees cope with the assigned tasks. Whether the work they do meets the applicable quality standards. How interested they are in their position, what professional results they have achieved. In other words, operational plans have a direct impact on employee motivation.

Some parts of operational work are cyclical in nature. For example, reports, mailings, congratulations to partners on holidays, birthdays, etc. Using modern business tools, it is possible to automate these processes. Quickly and professionally prepare operational plans with the help of electronic planning services.